What could be better than a custom-designed home? It can be shaped precisely based on any whim or wish, with an architect standing by to turn visions into bespoke built form. It can also be incredibly expensive.

OpenHome, a new joint venture between the architecture firms KieranTimberlake and Lake|Flato and the prefabricated-home builder Bensonwood, seeks to create a more accessible custom-home option. By combining prefabricated elements with architect-guided custom design treatments, the system brings wishful dream home design into the hands (and budgets) of the less than rich.

“Not everybody has the time or the resources to do a custom-built home, which might spend a year or two in design and a year or two in construction,” says KieranTimberlake’s Matt Krissel, project lead for OpenHome. The design system can halve the time it would take to build a fully custom home, and bring down the cost significantly.

“In order to make this process move faster and be more accessible to more people, it was really finding that balance of how much is custom and how much is part of the system,” Krissel says.

KieranTimberlake, Lake|Flato, and Bensonwood came together in 2018 to develop the concept and began taking on design projects in the spring of 2020.

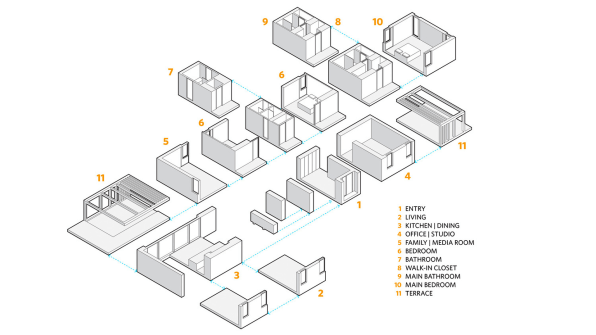

OpenHome is based on a series of building blocks, or clusters, that make up sections of rooms in a typical home. Built using prefabricated panels that Bensonwood makes in its factory, these clusters can be combined to create rooms of different sizes that can all connect together into a complete home, each designed to be all-electric and meet the low-carbon Passive House energy standard.

Working with an architect, homebuyers can define the spatial layout of their house and the types of rooms it will have by combining clusters from the OpenHome library. The pieces can be combined in a variety of shapes from narrow to wide, single- or double-story, in straight lines, perpendicular arrangements, or with interior courtyards.

“This is what allows us to swap out an extra bedroom or put in a larger bedroom, pull something apart and slip in a piece that didn’t exist, or rearrange the living room and kitchen relationship,” Krissel says. “We know how Bensonwood can build [each component], we have a design for them, and they can grow or contract for different needs or even shuffle around for different configurations.”

Krissel says the use of predesigned base components allows architects on his team to spend less time designing basic walls and closets and more time understanding the home’s site, its orientation, and the kinds of views and experiences the owner hopes to have. This partly involves visiting the site in person, but OpenHome also relies on a detailed 3D model of the design concept that the client can view in virtual reality.

Sun and seasonal modeling provide a sense for how the light will change in each room throughout the course of the year, and also help fine-tune the construction needs to ensure the home meets the high insulation requirements of the Passive House standard. Based on the client’s wishes, windows can be moved or enlarged, walls can be lengthened, and rooflines can be adjusted. Within three months, a design can be finalized.

“It’s a really effective tool for being able to operate at this pace,” Krissel says. “And acknowledging that a lot of people don’t actually understand floorplans or building sections, being able to model and walk people virtually through from early design really enhances our ability to get feedback.”

As the design gets closer to being finalized, the virtual reality tool is also used to help select the finishes for each room, from bathroom tiles to roofing materials.

Once the design is set, Bensonwood takes about two months to fabricate the panels in its factory. It also coordinates the building permit and work with a local contractor to begin laying the foundation and preparing for the on-site installation. The first home KieranTimberlake designed through the OpenHome process is now under construction in New Hampshire. Krissel says each of the partners in the joint venture has at least one OpenHome project in the works. KieranTimberlake is starting work on a second design now, and aims to be able to take on three to five per year to start.

“The goal is to be able to do these in less than a year, if [clients] can actually make all the decisions this fast,” Krissel says. “It’s a bit idealized, but the goal is that it’s substantially faster from beginning to end.”

The system brings architect-designed homes within reach of clients without the budget for a fully custom home. It also brings new opportunities to architects. “Now,” Krissel says, “we can say yes to projects that don’t have that luxury of a time frame or budget.”